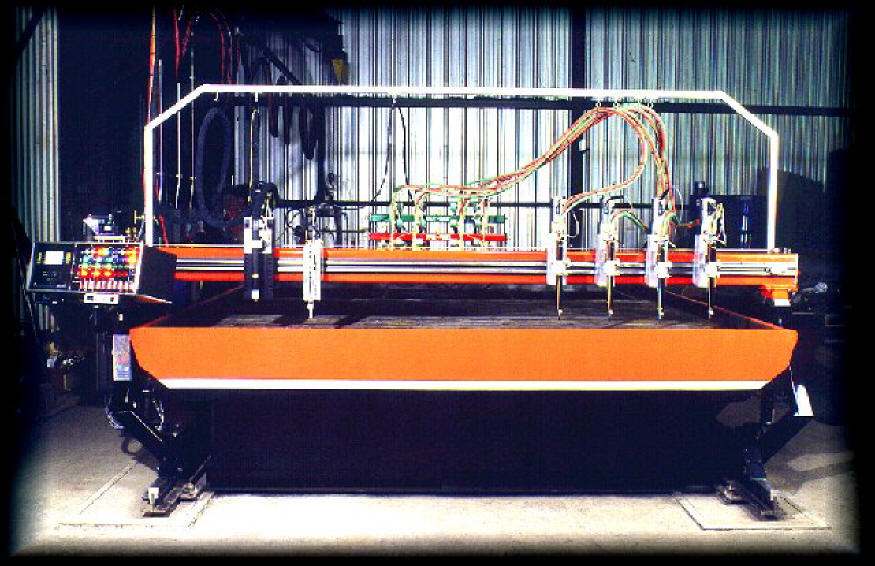

2000 Series Plasma and Oxy-Fuel Cutting Machines

This Inset Rail beam forward design was our first designed cutting machine ...

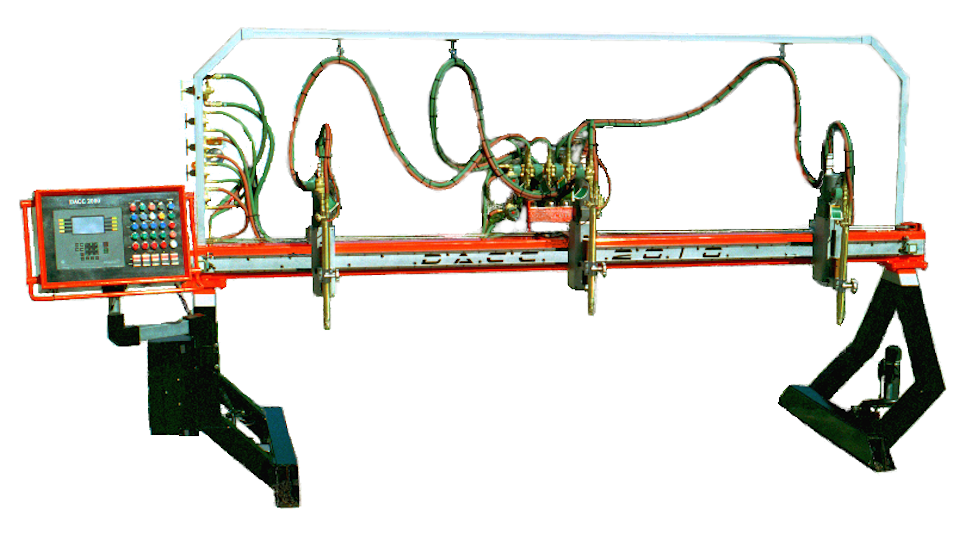

2000 Series Shape Cutting machine by DACC Industries

Above is a DACC2012HD with Hypertherm MAX200 Plasma cutting system with InnerLogic 401 automatic height control system, DACC3001 Air-Scribe plate marking system, DACC3606 high-volume dual gas manifold system, and 4 DACC2001 motorized torch lifters with DACC AccuLite ignition system and Smith Oxy-Fuel torches. 144" X 240" cutting capacity and 500 IPM PWM servo drive system. All controlled by the DACC2206 Operations control panel. PicoPath CNC control and Linatrol Servo drive system by Northrup Grummen

Product Summary

Welcome to the future of Shape Cutting Technology with the introduction of the DACC 2000 series shape cutting machines. Finally a machine designed for maximum versatility for both operation and productivity. Innovative machine frame design, along with our 2000 series Operator Control Consoles, brings forth a new era in shape cutting machines. Since the introduction of the shape cutting machines, little change has been made to the operations or the frame design. For so long the industry has just allowed innovative electronic hardware to be its primary evolution in technology, until now. “A New Shape for Shape Cutting Technology” has come to life and is taking the market by storm. With features like “Smart Interface Console”, “Inset Rail System”, “Fixed Mirroring Positioning”, “(A) Frame Design”, it's no wonder the DACC 2000 series shape cutting machines are so versatile.

Key Features

- Inset Rail System

DACC 2000 series machines all have our “Inset Rail System” which provides a smaller footprint, requiring less square footage, as well as a safer work environment for the operator: that is, no more crawling or tripping over rails. No more being caught between the cutting table and the machine frame. With this system rails are protected from debris and damage due to their under-the-table design. DACC was the first to offer a large “Gantry Machine” that leaves the work table open for loading and unloading materials by a fork-lift

- "FMP" CrossDrive System

The “Fixed Mirroring Positioning” crossdrive system was engineered to be stable and accurate. By removing the servo drive from the cutting process (Fixed), using easy-to-operate front and rear locks for (Mirroring) and (Positioning), and Rockwell C60 linear V-rails with compact carriage assemblies has proven to be one of the most reliable crossdrive systems ever built. DACC cutting machines are creating new standards in machine performance.

- Innovations

The “User-Friendly” concepts of DACC are setting new standards for cutting machine operation and productivity. Operators love the added functionality they get with the DACC 2000 operations consoles for the Oxy-fuel Flame cutting process, Plasma cutting process, and the Plate marking process. With features like “Smart Interface Console”, “Inset Rail System”, “Fixed Mirroring Positioning”, “(A) Frame Design”, and the only large “Gantry Machine” that leaves the work table open for loading and unloading materials by a fork-lift, it's no wonder the DACC 2000 series shape cutting machines are so versatile.

- Savings, Performance, Production

The DACC 2000 Series Shape Cutting Machine is a Gantry machine with a Cantilever feel. But, unlike the Cantilever, and most Gantry machines, it uses only 20% more space than its own cutting width. This new design gives increased stability over the full speed range of the machine. With speeds available up to 1000 IPM, this can make a real difference in productivity and performance.

- Custom Sizes

The DACC 2000 Series Shape Cutting Machines are available in a wide range of sizes, from 60" cutting width to 384" cutting width, and all machines can be custom built for your particular application.

AccuJet Water Jet Cutting Machines

Our inovative ideals in shape cutting technology has brought our New line of Water Jet Cutting Machines

A Better Shape for Shape Cutting

The Inset Rail Design by DACC Industries creates a safer work inviroment for the operator and the fact you can use a forklift to load and unload the table..

Custom Cutting Machines

Custom Bevel cutting machine with 800 amp plasma and Oxy-Fuel

HVAC and Light Fabracation

AccuPlasma and AccuLiner for the HVAC cutting was the first at 2000 IPM Traversing with no "wiggles and no Jiggles"

AccuJet Precision Water Jet Cutting

AccuJet Water Jet Cutting Systems for precision cutting of all types of materials

ShapeTech Cutting Technology

Leading the industry in high speed water only cutting technology upto 3000 ipm

Thank You for joining us on our website

... If you have any questions please call (225)921-8489 ...

We recommend using Crome or Mozilla Firefox for your browser